The Future of Additive Manufacturing: Trends to Watch

How Emerging Technologies Are Redefining the Boundaries of 3D Printing and Global Production

🌍 Introduction: A New Industrial Epoch

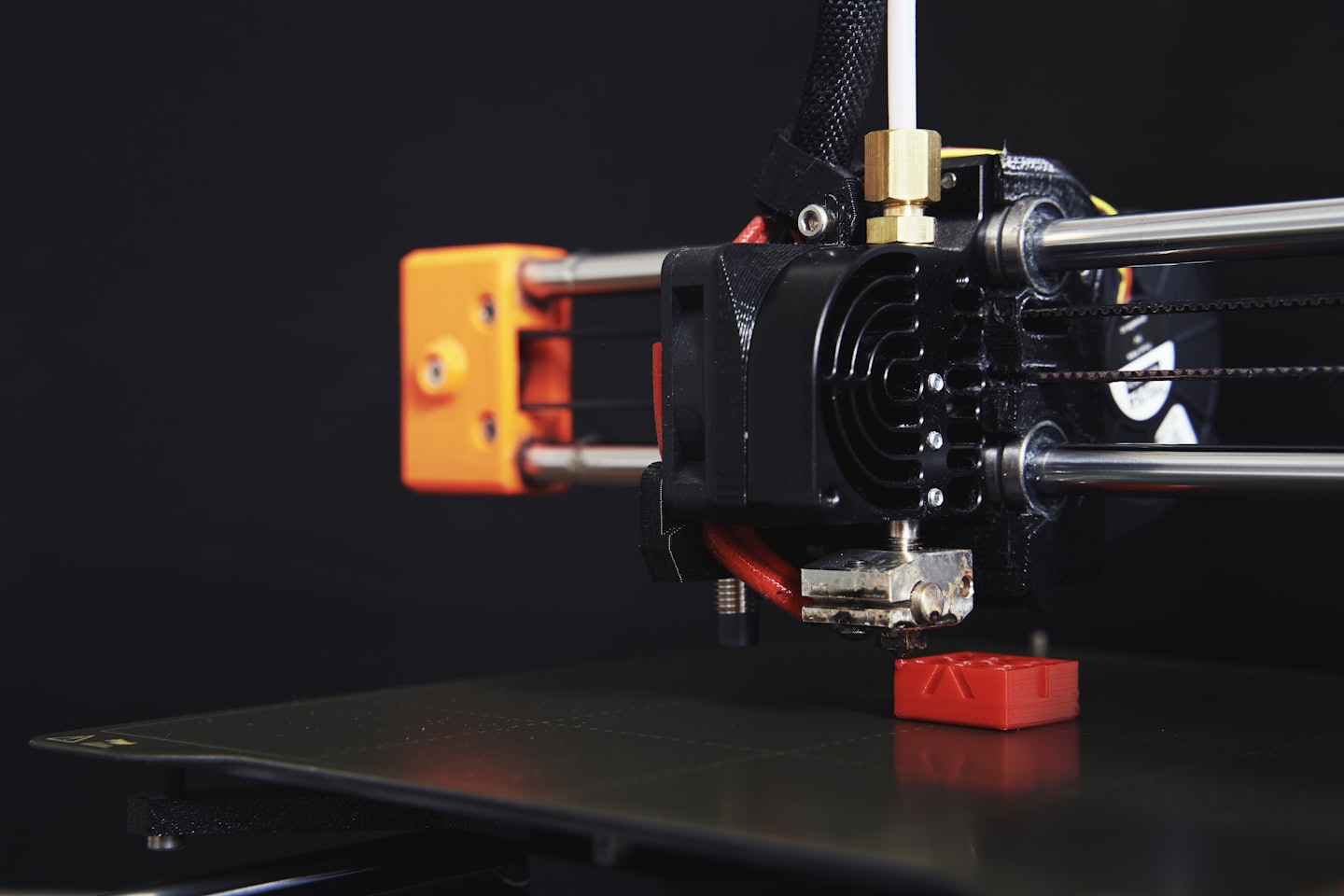

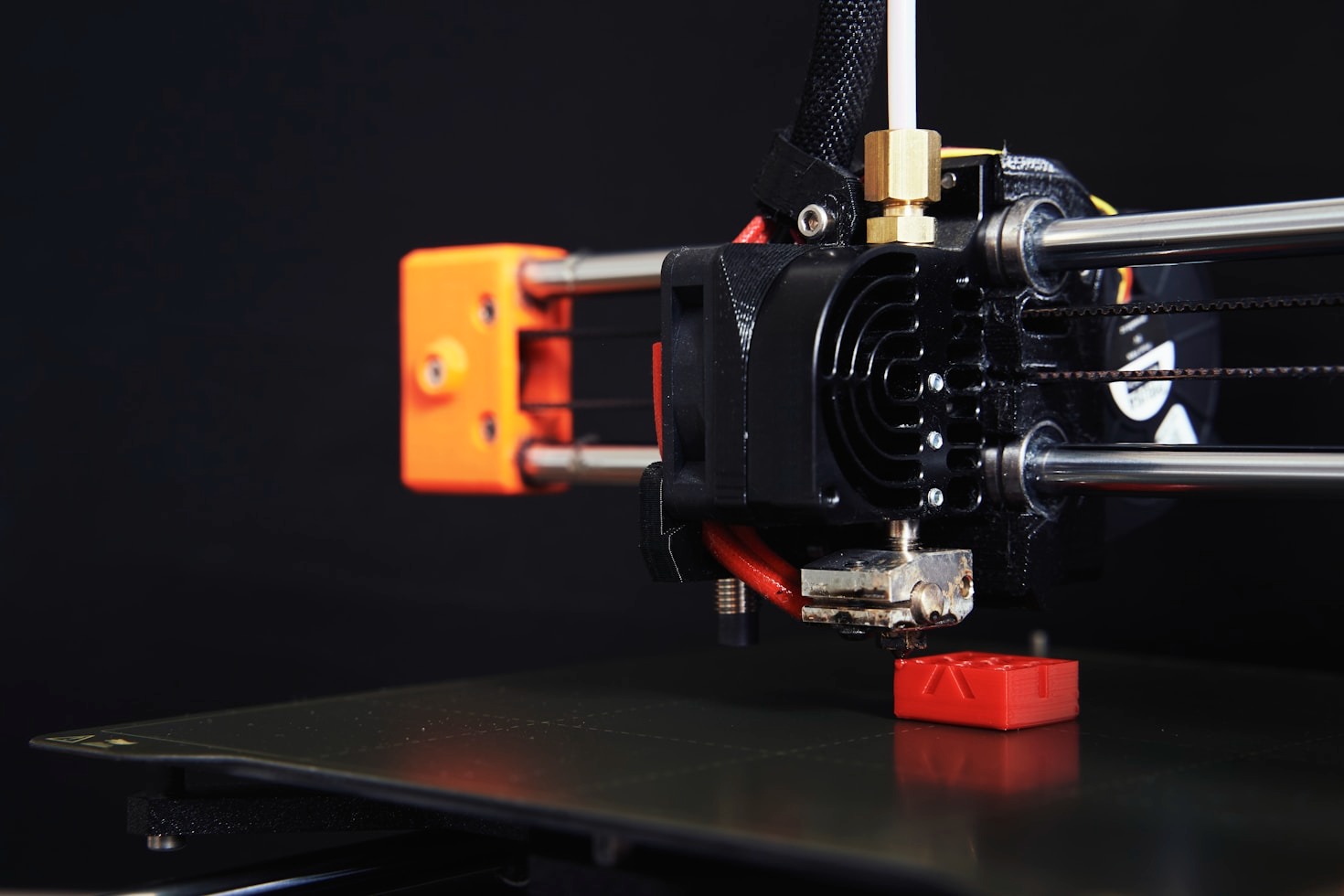

Additive manufacturing (AM) — once synonymous with prototyping — is now one of the defining pillars of the Fourth Industrial Revolution.

What started as an experimental process in the 1980s has evolved into a global production force driving transformation across aerospace, healthcare, construction, energy, automotive, and consumer products.

Today, 3D printing stands at the intersection of AI, robotics, quantum computing, and blockchain, signaling the dawn of a new era — one where manufacturing is intelligent, decentralized, and infinitely adaptive.

The next decade of additive manufacturing will be characterized not only by new materials and machines, but by a shift in how we design, distribute, and democratize innovation.

Here’s an in-depth look at the trends that will define the future of AM — and how they’re reshaping the global economy.

🧠 1. AI-Driven Design and Predictive Manufacturing

Artificial Intelligence (AI) has moved from theory to practice in the world of additive manufacturing.

AI algorithms can now predict part failures, optimize print parameters, and autonomously adjust print settings in real time — all without human intervention.

How It’s Changing the Game:

-

Generative Design: AI analyzes performance requirements and produces thousands of optimized part geometries that no human could manually design.

-

Predictive Maintenance: Machine learning models detect anomalies in real time, reducing downtime and waste.

-

Adaptive Manufacturing: Intelligent printers learn from every print, continuously improving their accuracy and efficiency.

Companies are integrating AI-driven design software into their workflows, enabling a new paradigm called Design for Additive Manufacturing (DfAM) — where machines not only build, but also think.

“In the factory of the future, design isn’t done by engineers alone — it’s co-created with algorithms.”

🧬 2. The Rise of Advanced Materials

The evolution of 3D printing materials is expanding what’s possible far beyond plastics.

From metals and ceramics to composites, nanomaterials, and biocompatible polymers, new formulations are unlocking capabilities in strength, conductivity, and environmental resilience.

Key Material Trends:

-

High-Performance Metals: Titanium, Inconel, and aluminum alloys dominate aerospace and defense applications.

-

Composites: Carbon fiber and glass-filled filaments enhance stiffness and temperature resistance.

-

Bio-Based Polymers: Sustainable and biodegradable materials are entering mainstream production.

-

Smart Materials: 4D printing materials that change shape or function in response to heat, light, or magnetic fields.

The integration of material science with additive manufacturing is enabling multi-material printing, where a single machine can print complex assemblies with varying properties — conductive, flexible, or structural — all in one process.

🏭 3. Distributed Manufacturing and Digital Supply Chains

The COVID-19 pandemic revealed how fragile global supply chains can be.

Additive manufacturing offers a powerful alternative: on-demand, localized production supported by digital design files instead of physical inventory.

The Emerging Model:

-

Digital Warehouses: Spare parts are stored as design files, printed anywhere on demand.

-

Local Microfactories: Decentralized print hubs enable rapid response to regional needs.

-

Blockchain Integration: Immutable design tracking ensures security and authenticity across global networks.

This shift from centralized mass production to distributed, data-driven fabrication is giving rise to the “Manufacturing-as-a-Service (MaaS)” model — where digital blueprints flow across secure global networks and machines do the rest.

“The next global supply chain will run on code, not cargo.”

🪙 4. Tokenized Manufacturing and Blockchain Integration

Blockchain technology is quietly becoming the trust layer for additive manufacturing.

It provides a secure, transparent system for tracking designs, verifying intellectual property, and automating transactions through smart contracts.

Real-World Applications:

-

IP Protection: Every 3D model can be time-stamped, licensed, and tracked across distributed networks.

-

Smart Contracts: Automatic royalty payments for creators and suppliers when designs are printed.

-

Traceability: Immutable ledgers track material origins and production processes for compliance and quality assurance.

The combination of 3D printing + blockchain ensures that global collaboration can scale without compromising trust — paving the way for decentralized ecosystems of design, production, and innovation.

⚙️ 5. Industrial-Scale Automation and Robotics

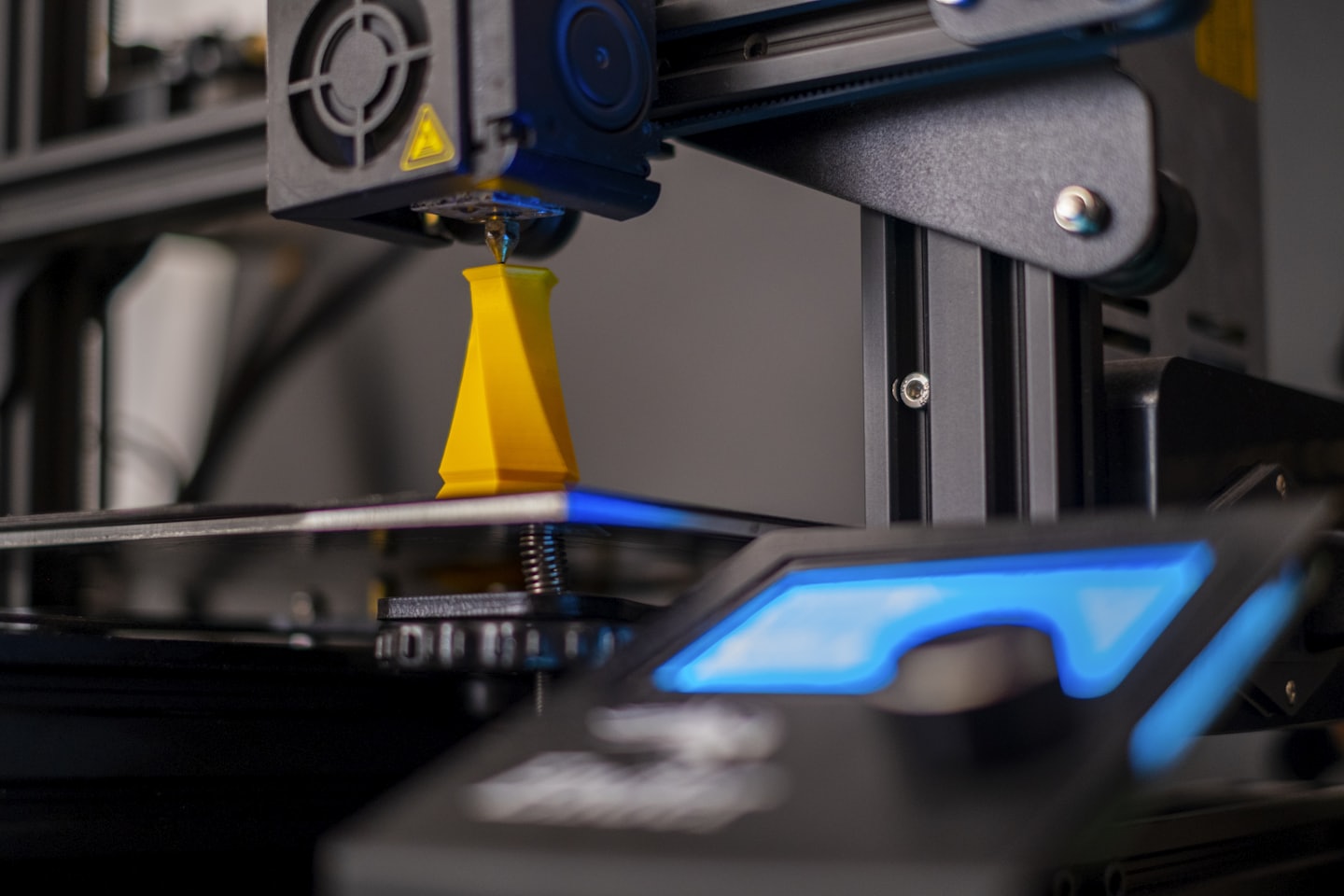

Additive manufacturing is increasingly merging with robotics, automation, and machine vision to create fully autonomous production lines.

Instead of one printer producing one part, robotic arms now operate in coordinated print cells capable of handling multiple materials, orientations, and post-processing steps.

Future Manufacturing Systems:

-

Hybrid Machines: Combining additive and subtractive methods for precision finishing.

-

AI-Powered Robot Arms: Real-time correction and assembly integration.

-

Continuous Printing Systems: Conveyor-based printers that operate 24/7 for industrial-scale output.

Factories are evolving into smart, self-managing ecosystems, where robots, sensors, and AI collaborate to create a seamless flow from design to finished product — a concept often called the Machine Economy.

🧬 6. Bioprinting and Regenerative Manufacturing

Bioprinting — the use of 3D printing technologies to fabricate tissues, organs, and biomaterials — is one of the most transformative frontiers of AM.

Current and Emerging Applications:

-

Tissue Engineering: Printing cartilage, skin grafts, and bone structures using bioinks.

-

Drug Testing and Discovery: Printing organ-on-a-chip systems to test pharmaceutical responses.

-

Regenerative Medicine: Long-term vision of printing fully functional organs for transplant.

While still in early development, bioprinting has already advanced from laboratory research to clinical trials. It promises a future where medical treatment is personalized, ethical, and infinitely replicable — layer by layer.

🏗️ 7. Large-Scale Construction Printing

3D printing is revolutionizing how we build homes, offices, and infrastructure.

Construction-scale printers now use cement-based, sand, or recycled materials to create entire structures directly from digital designs.

Key Benefits:

-

Speed: Homes can be printed in under 48 hours.

-

Cost Savings: Labor and waste reductions lower housing costs.

-

Sustainability: Use of local and recycled materials reduces environmental impact.

From social housing projects in Latin America to futuristic smart cities in the Middle East, construction printing represents a leap toward sustainable urbanization and affordable global housing.

“Tomorrow’s cities will be printed, not built.”

🌐 8. The Convergence of Quantum Computing and Additive Manufacturing

Quantum computing may sound distant, but its implications for additive manufacturing are profound.

By processing data on a subatomic level, quantum algorithms can simulate materials, optimize print parameters, and predict part performance with unprecedented precision.

Future Applications:

-

Quantum Simulation: Accelerated discovery of new materials and composites.

-

Design Optimization: Solving complex geometries that classical computers can’t handle.

-

Supply Chain Efficiency: Real-time optimization of logistics, cost, and production flow.

In essence, quantum-enhanced additive manufacturing will make it possible to design materials before they exist — transforming innovation from reactive to predictive.

🌱 9. Sustainability and the Circular Manufacturing Model

Environmental responsibility is now a defining principle of manufacturing innovation.

Additive manufacturing’s intrinsic efficiency — using only the material required for each part — gives it a natural sustainability edge.

Green Trends to Watch:

-

Recyclable and Bio-Based Materials: Filaments and powders made from renewable sources.

-

Closed-Loop Printing Systems: Printers that recycle waste material directly into new prints.

-

Localized Production: Reduces shipping and carbon emissions.

As industries aim for net-zero emissions, 3D printing is emerging as a cornerstone of circular economy models, enabling waste-free production and localized, low-carbon supply chains.

📡 10. Education, Workforce Evolution, and the Rise of the “Digital Craftsman”

As additive manufacturing becomes mainstream, the workforce must evolve.

Universities and corporations are rapidly integrating additive manufacturing, robotics, and digital fabrication into engineering curricula and vocational training.

The future professional will be a “digital craftsman” — equally fluent in design software, materials science, AI, and production strategy.

What’s Ahead:

-

Virtual Learning Platforms: Immersive simulation labs for design and printing.

-

Cross-Disciplinary Training: Combining data science, design, and engineering.

-

Entrepreneurial Ecosystems: Accelerators focused on additive startups and creative fabrication.

Education will be the bridge between the digital revolution and human creativity — ensuring that innovation remains both technological and human-centered.

🚀 11. The Economic Shift: From Ownership to Access

As digital manufacturing matures, we’re seeing the emergence of manufacturing-on-demand economies.

Instead of owning equipment, companies will increasingly rely on cloud-based fabrication services — where 3D printers are networked and accessible remotely, similar to cloud computing.

This “access over ownership” model allows startups and small enterprises to scale globally without heavy infrastructure, democratizing innovation across every industry.

🔮 Conclusion: Printing the Future

The future of additive manufacturing isn’t just about better machines or faster prints — it’s about rethinking the entire architecture of creation.

From autonomous print farms and AI-generated designs to quantum-simulated materials and blockchain-verified supply chains, we are entering an era where manufacturing becomes intelligent, decentralized, and adaptive.

Additive manufacturing will not simply complement traditional industries — it will redefine them.

It promises a world where products are designed collaboratively, printed locally, and distributed digitally.

“The next industrial revolution won’t be built on assembly lines — it will be printed, one layer at a time.”

Leave a Reply