How 3D Printing Is Transforming Industries Worldwide

From Aerospace to Healthcare, Additive Manufacturing Is Reshaping How the World Designs, Builds, and Innovates

🌍 Introduction: A Quiet Revolution in Motion

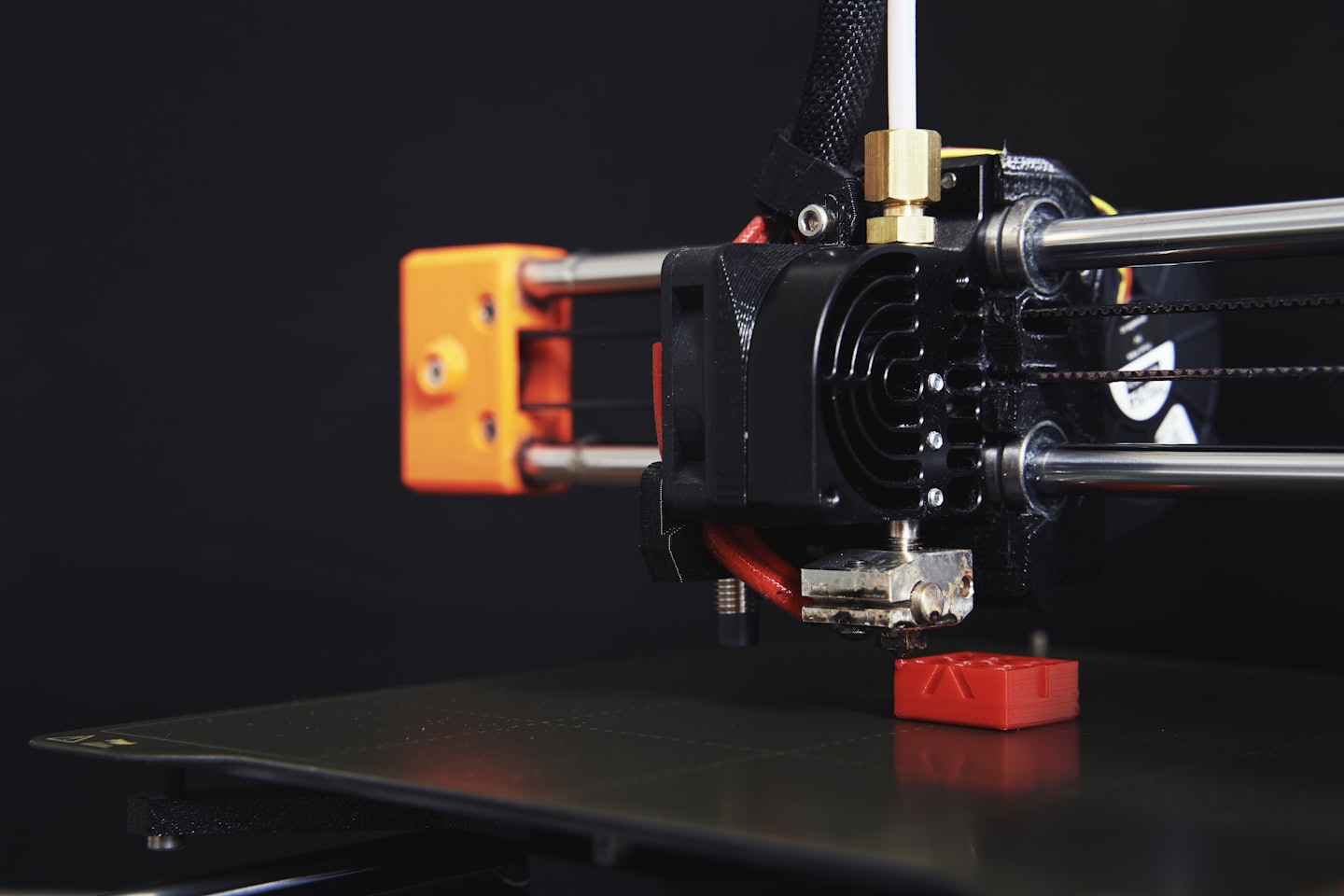

Once seen as a futuristic novelty, 3D printing — or additive manufacturing — has become one of the most powerful forces driving industrial transformation across the globe.

By turning digital blueprints into physical objects layer by layer, it has fundamentally altered how products are conceived, produced, and delivered.

What began as a niche tool for rapid prototyping is now a multi-billion-dollar global industry spanning aerospace, healthcare, automotive, construction, and beyond.

As manufacturing becomes increasingly digital and decentralized, 3D printing is leading a revolution — one defined by efficiency, customization, and sustainability.

🛫 Aerospace: Printing the Future of Flight

Few industries have embraced 3D printing as aggressively as aerospace.

Companies like Airbus, Boeing, and GE Aviation are using additive manufacturing to create lightweight, complex parts that were once impossible or prohibitively expensive to produce.

Key Impacts:

-

Weight Reduction: Metal 3D printing allows engineers to design parts with internal lattice structures, reducing weight while maintaining strength.

-

Fuel Efficiency: Every gram saved translates to lower fuel consumption and emissions.

-

On-Demand Parts: Airlines can print replacement components on-site, reducing downtime and logistics costs.

GE Aviation’s LEAP jet engine now includes 3D-printed fuel nozzles that are 25% lighter and five times more durable than traditional ones — a landmark case of engineering innovation meeting sustainability.

🏥 Healthcare: Personalized Medicine in Action

In healthcare, 3D printing has moved from experimental to essential.

Surgeons, biomedical engineers, and pharmaceutical companies are harnessing the technology to personalize care and improve patient outcomes.

Transformative Uses:

-

Custom Implants and Prosthetics: 3D scanning allows creation of patient-specific bones, joints, and dental components with near-perfect anatomical accuracy.

-

Surgical Planning Models: 3D-printed replicas of organs and tumors let doctors rehearse complex procedures before entering the operating room.

-

Bioprinting and Tissue Engineering: Researchers are printing living cells and scaffolds to explore future possibilities of organ regeneration.

From custom hearing aids to titanium skull implants, additive manufacturing is bridging the gap between medical science and individual human need.

🚗 Automotive: Accelerating Innovation from Design to Production

The automotive sector is experiencing a renaissance powered by additive manufacturing.

Once limited to prototyping, 3D printing now plays a crucial role in tooling, parts production, and electric vehicle innovation.

Key Impacts:

-

Rapid Prototyping: Design cycles that once took months now take days.

-

Lightweight Components: 3D-printed brackets, ducts, and housings cut vehicle weight, improving fuel economy.

-

Customization: Manufacturers can offer limited-edition or custom-designed interiors and accessories at scale.

Companies like Ford, BMW, and Volkswagen now use additive manufacturing across multiple production lines — proving that digital fabrication can coexist with industrial mass production.

🏗️ Construction: Building the Cities of the Future

In construction, 3D printing is doing something extraordinary — turning digital designs into full-scale buildings.

Using robotic arms and cement-based extruders, engineers are now constructing entire homes, bridges, and offices directly from digital models.

Advantages:

-

Speed: Houses can be printed in as little as 24 hours.

-

Affordability: Reduced labor and material costs make housing more accessible.

-

Sustainability: Less waste and the ability to use recycled materials make 3D-printed buildings environmentally friendly.

Projects in Dubai, Mexico, and the Netherlands have already demonstrated the viability of large-scale printed architecture, hinting at a future where sustainable, customizable housing is available to everyone.

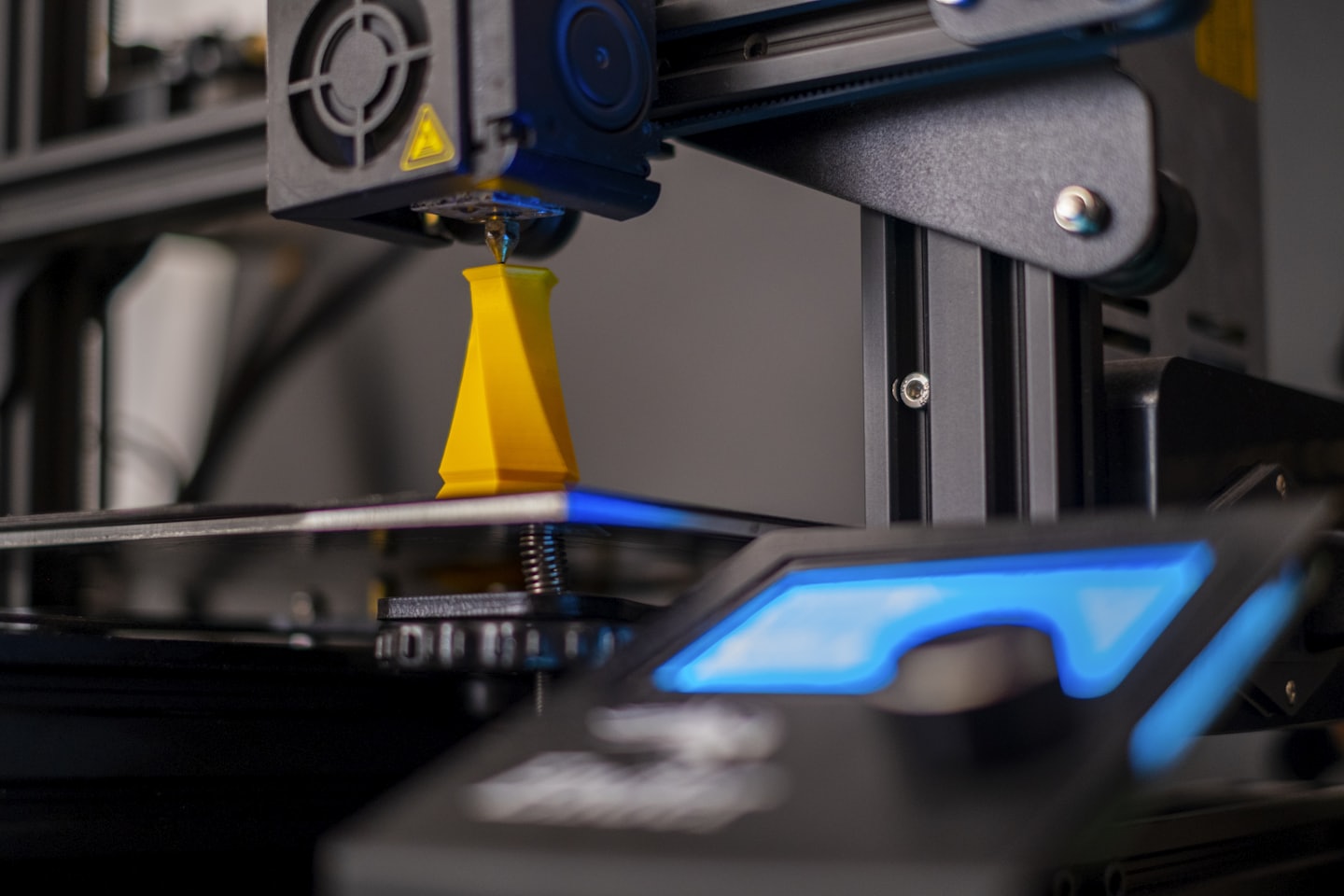

🏭 Manufacturing: From Mass Production to Mass Customization

Traditional manufacturing is built on economies of scale. 3D printing flips that logic — enabling economies of one.

It’s no longer about producing millions of identical items, but rather millions of uniquely optimized parts.

Key Transformations:

-

Localized Production: Companies can print components where and when they’re needed, cutting supply-chain costs.

-

Inventory Digitization: Digital design files replace massive warehouses filled with spare parts.

-

Complex Geometry: Additive methods allow production of intricate designs impossible through conventional manufacturing.

This “digital supply chain” model reduces dependence on centralized factories and makes manufacturing more resilient, distributed, and adaptive — lessons that proved invaluable during global disruptions like the COVID-19 pandemic.

🎨 Consumer Goods and Fashion: Creativity Without Limits

In the world of fashion, jewelry, and design, 3D printing empowers artists and brands to break free from traditional constraints.

Designers are now experimenting with custom footwear, eyewear, and even haute couture clothing that merges digital art with material science.

Luxury brands use 3D printing for rapid prototyping, limited editions, and unique geometries that were once impossible to craft by hand.

Even global giants like Adidas and New Balance use additive manufacturing for custom midsoles and athletic gear, blurring the line between art, technology, and personalization.

⚗️ Energy and Industrial Equipment: Efficiency Through Complexity

Energy companies are leveraging 3D printing to develop turbine blades, heat exchangers, and drilling tools that perform better and last longer.

-

Design Freedom: Internal cooling channels and optimized shapes increase efficiency.

-

Maintenance Efficiency: Damaged parts can be reprinted on-site, reducing downtime.

-

Sustainability: Material waste is significantly reduced compared to subtractive machining.

This blend of digital precision and material efficiency is helping energy firms meet sustainability goals while maintaining performance under extreme conditions.

🧬 Education and Research: Shaping the Next Generation

Around the world, universities and technical institutes are embedding 3D printing into STEM education.

Students are learning not just how to print objects, but how to design systems, optimize materials, and think like innovators.

Collaborative research projects are also driving breakthroughs in nanoprinting, smart materials, and biofabrication — creating an entirely new discipline of digital engineering.

By democratizing design and manufacturing knowledge, 3D printing is empowering a new wave of global problem solvers.

🌱 Environmental Sustainability: Printing a Greener Tomorrow

3D printing inherently produces less waste — using only the material necessary to build each part.

But its real environmental impact lies in localization and circular design.

Sustainability Advantages:

-

Reduced shipping emissions through local production.

-

Recycling of plastics and metals into printable feedstock.

-

Biodegradable and bio-based material development.

From 3D-printed coral reefs restoring marine habitats to upcycled polymers creating sustainable fashion, additive manufacturing is becoming a catalyst for climate innovation.

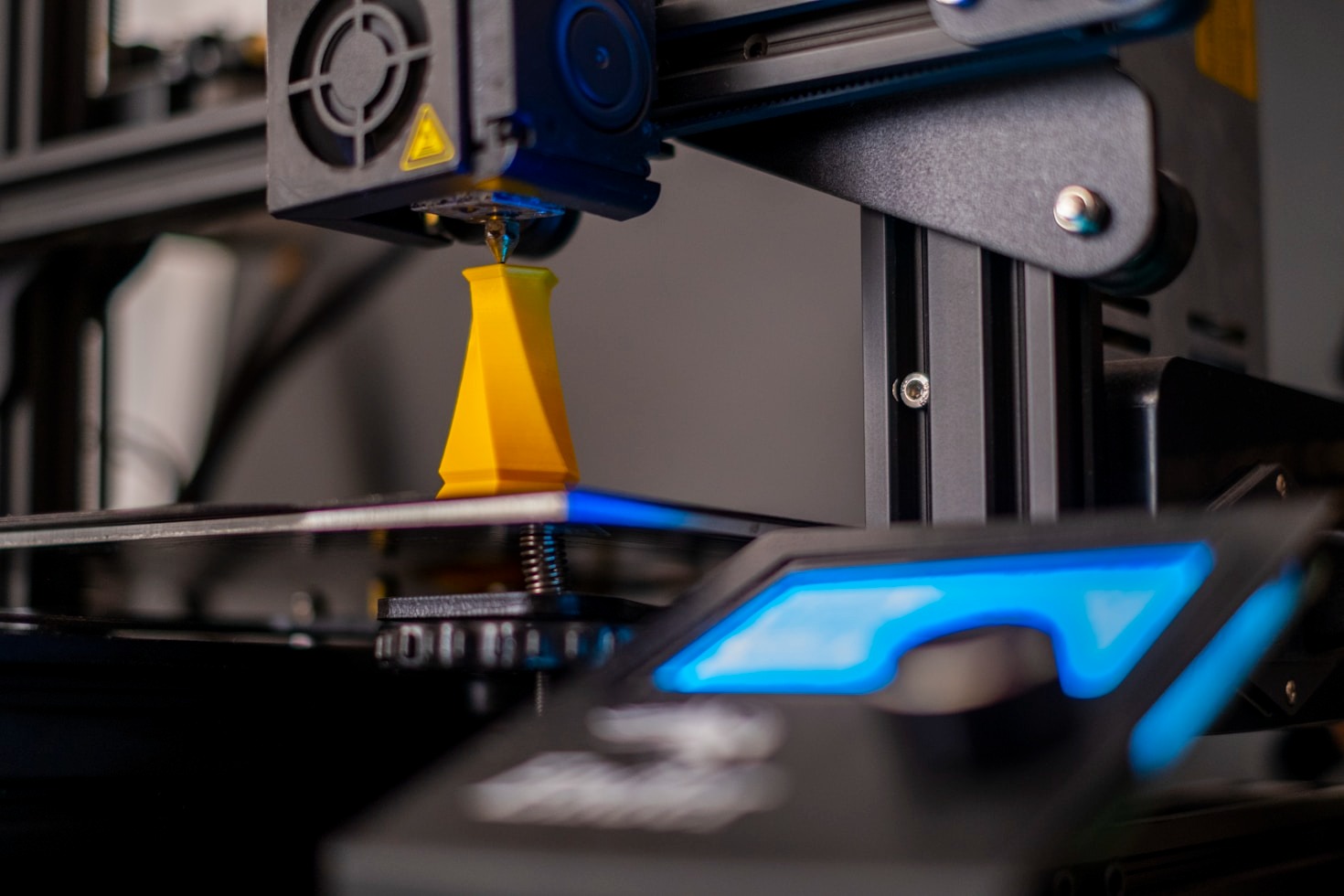

🚀 The Future: A World Built Layer by Layer

3D printing is not replacing traditional manufacturing — it’s reinventing it.

By combining automation, data, and design intelligence, it’s unlocking a new era of flexibility, decentralization, and innovation.

The industries of tomorrow — from aerospace to medicine — won’t just use 3D printing as a tool; they’ll use it as a foundation for creativity, resilience, and sustainability.

“The next industrial revolution won’t happen in one factory or one country — it will happen everywhere, one layer at a time.”

Leave a Reply