How to Stay Ahead in Additive Manufacturing

Strategies, Tools, and Trends for Thriving in a Rapidly Evolving Industry

🌍 Introduction: The New Industrial Frontier

Additive manufacturing (AM) — once synonymous with “3D printing” — has evolved into one of the most dynamic, fast-changing sectors in modern industry. What began as a niche tool for prototyping is now a multibillion-dollar ecosystem shaping aerospace, healthcare, energy, consumer goods, and even bioprinting.

Yet in a world where innovation cycles move at the speed of software, staying ahead in additive manufacturing requires more than technical know-how. It demands strategic awareness, continuous learning, collaboration, and adaptability.

From automation and AI to blockchain and quantum design, the technologies fueling this transformation are converging. The companies — and individuals — that thrive will be those that anticipate trends, adopt digital tools early, and connect into the growing global additive network led by platforms like:

-

3D Printing Central – the global directory and resource hub for the entire AM ecosystem.

-

3D Printing Channel – the media and education platform connecting innovators and investors.

-

Association of 3D Printing – fostering standards, ethics, and training across the industry.

-

3D Printing Ventures – empowering innovation through investment and commercialization.

-

Bioprinting World – expanding the future of regenerative medicine and biofabrication.

-

3D Printing Coin ($3DP) – tokenizing collaboration, value creation, and digital manufacturing economies.

Together, these organizations form the 3D Printing Network — an integrated ecosystem advancing global additive innovation.

“To stay ahead in additive manufacturing, you don’t just adopt technology — you join the network that’s building the future.”

⚙️ 1. Master the Technology Stack

The first step to staying ahead is understanding the interconnected technologies driving additive manufacturing forward.

These are no longer separate disciplines — they’re interdependent layers of one intelligent system.

The Core Stack of Modern Additive Manufacturing:

-

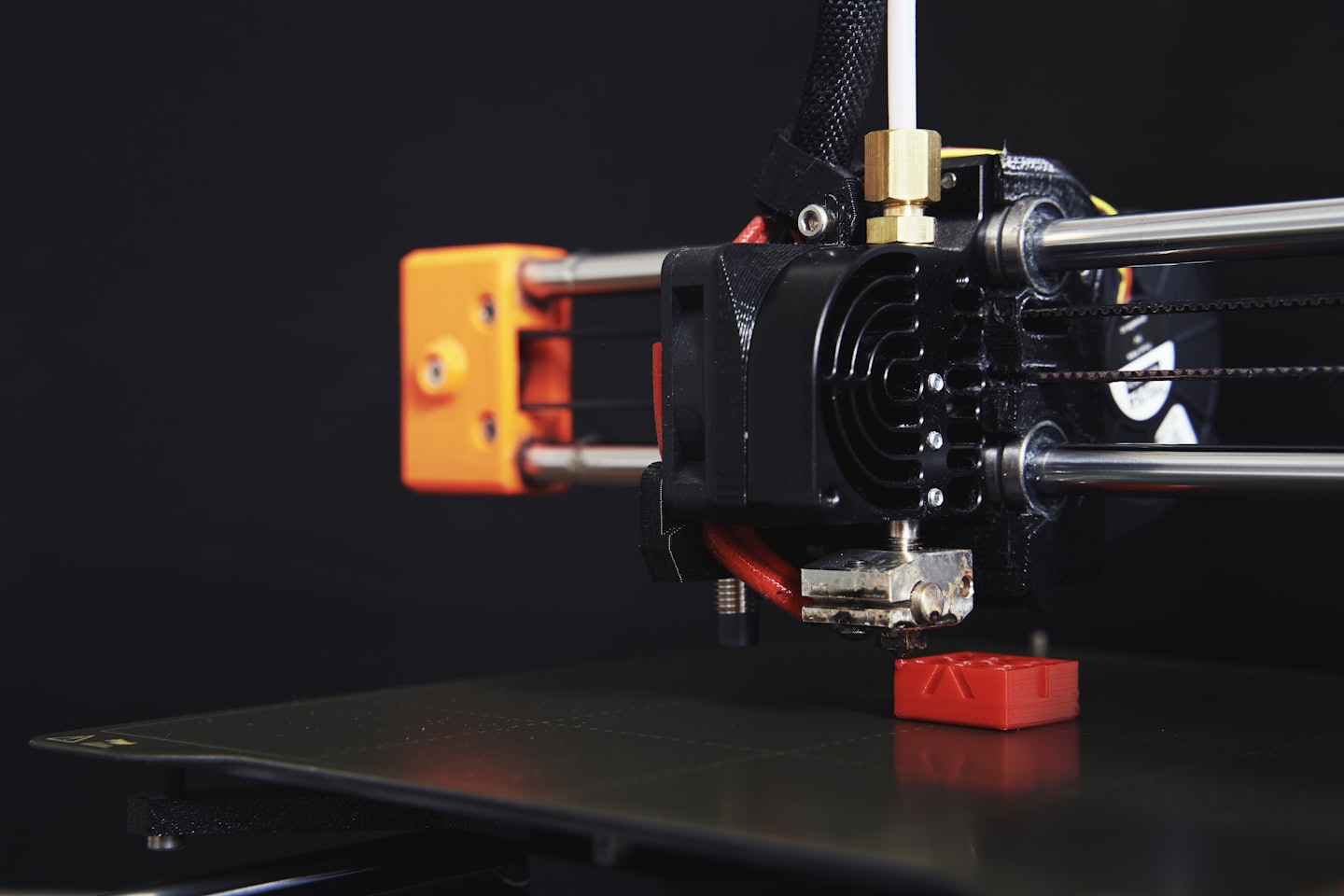

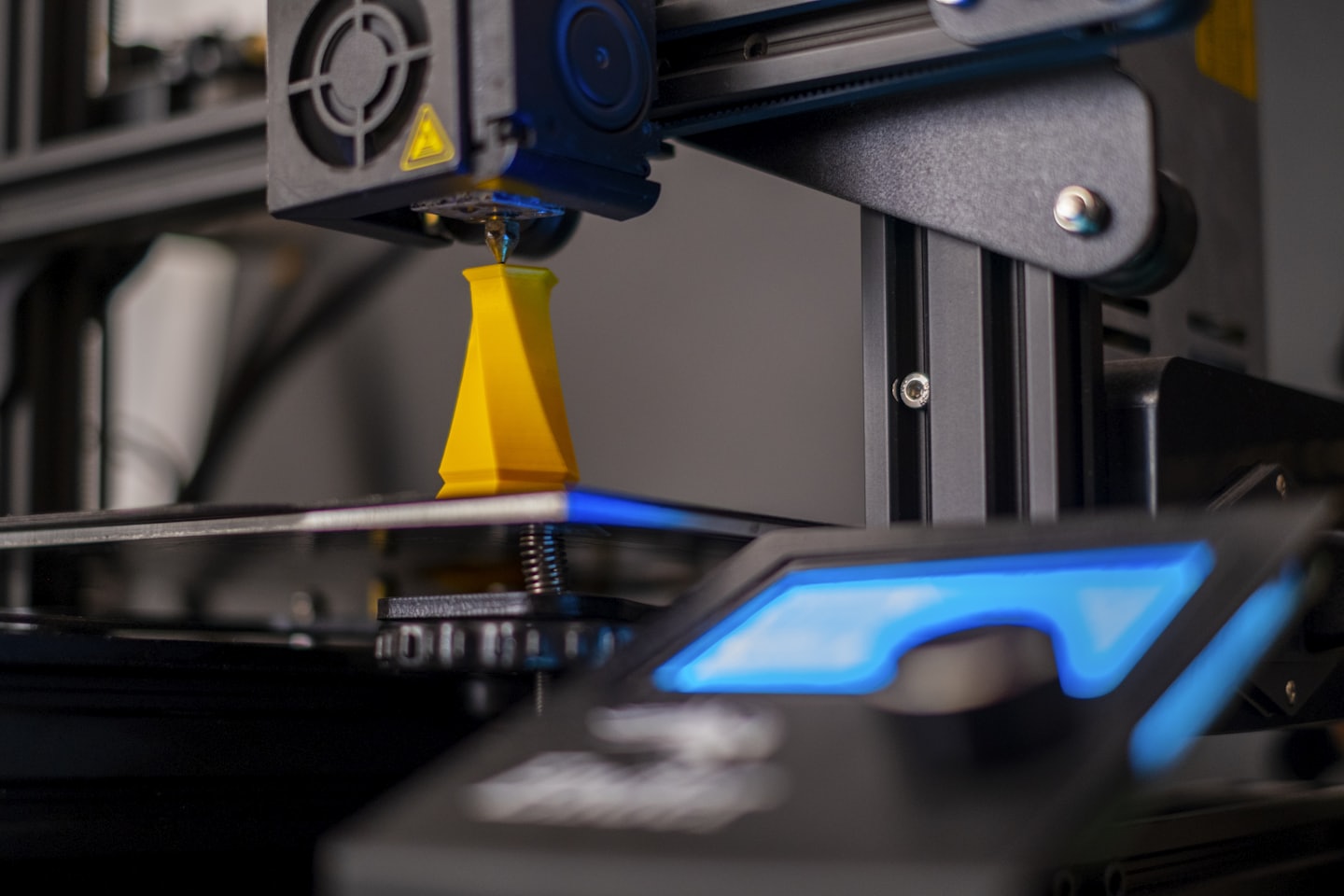

3D Printing Hardware: From FDM and SLS to metal AM and multi-material bioprinters, hardware innovation is expanding print size, speed, and resolution.

-

AI & Machine Learning: Generative design, process optimization, and predictive maintenance rely on AI systems that make printing smarter and more efficient.

-

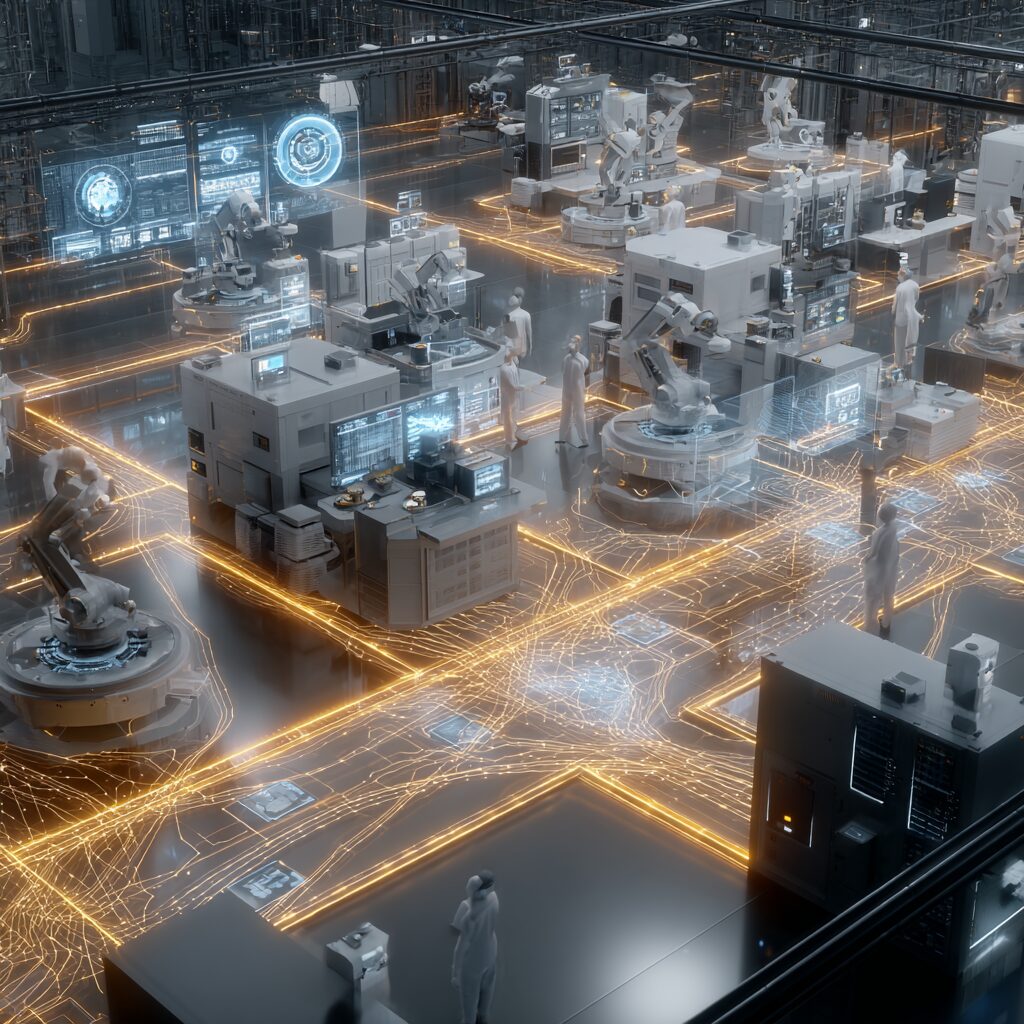

Robotics & Automation: Autonomous printer farms and robotic post-processing enable mass production with minimal human intervention.

-

Blockchain Integration: Securely manages digital files, ensures traceability, and supports decentralized manufacturing networks.

-

Quantum & Simulation Software: Accelerates material discovery and optimization at the molecular level.

By mastering not just the printer, but the ecosystem around the printer, professionals position themselves as architects of the future factory.

“Additive manufacturing no longer exists in isolation — it’s the nexus where software, data, and machines converge.”

🧠 2. Invest in Continuous Learning and Training

Technology evolves faster than most companies can adapt. To stay relevant, learning must become a permanent part of the job description.

Ways to Keep Learning:

-

Professional Certifications: Programs through the Association of 3D Printing and major technical institutes now offer additive manufacturing credentials recognized worldwide.

-

Online Courses and Webinars: Platforms like 3D Printing Channel feature expert interviews, tutorials, and event coverage that make lifelong learning accessible.

-

Executive Education: Programs like the 3D Printing MBA bridge business strategy with additive technology, helping leaders turn knowledge into enterprise growth.

-

Industry Conferences: Events such as Formnext and RAPID + TCT expose attendees to the latest breakthroughs and partnerships.

Education in AM isn’t just technical — it’s strategic. The leaders of tomorrow must understand both the science of printing and the economics of innovation.

🤝 3. Build a Strong Network of Collaborators

In a decentralized manufacturing world, connection is currency.

No single company or individual can master all aspects of additive manufacturing — but together, networks can.

How to Build Your Additive Network:

-

Join professional associations like the Association of 3D Printing for access to industry events, forums, and mentorship programs.

-

Engage with the 3D Printing Channel to stay visible in the community and share your expertise.

-

Partner with investors or incubators like 3D Printing Ventures to fund new product development or scale emerging technologies.

-

Contribute to open-source or tokenized projects supported by 3D Printing Coin ($3DP) to build reputation and reward innovation.

The additive economy thrives on collaboration over competition. Those who network deeply will always have access to better ideas, resources, and opportunities.

🪙 4. Embrace Tokenization and Digital Value Exchange

The blockchain economy is becoming a fundamental layer of manufacturing.

Tokenization allows machines, designers, and companies to exchange value seamlessly without intermediaries — enabling faster funding, fairer royalties, and global transparency.

Through 3D Printing Coin ($3DP), designers can:

-

License or sell digital designs securely.

-

Participate in tokenized investment rounds for new technologies.

-

Earn rewards for educational contributions, research, or open-source innovation.

By adopting blockchain early, businesses future-proof their intellectual property, streamline transactions, and open new revenue models — from machine-to-machine payments to decentralized manufacturing marketplaces.

“Tokenization transforms creativity into a global economy of ideas.”

🤖 5. Adopt Automation and Smart Manufacturing

Automation is the new competitive advantage. AI-powered robotics, autonomous printer farms, and real-time quality control systems are redefining productivity.

The leaders in AM are investing in:

-

Autonomous Robotics Systems: Capable of round-the-clock operation and self-correction.

-

Integrated Sensor Networks: Monitoring temperature, layer adhesion, and mechanical accuracy in real time.

-

Cloud-Connected Factories: Linking printers globally through shared blockchain and AI infrastructures.

Platforms like 3D Printing Ventures are funding the next generation of companies that combine robotics, blockchain, and 3D printing into self-optimizing factories — the foundation of what’s now called the Machine Economy.

🌱 6. Prioritize Sustainability and Material Innovation

Sustainability is no longer optional — it’s a driver of innovation and profitability. Additive manufacturing inherently reduces waste, but the real leaders are going further.

Key Trends in Green AM:

-

Recyclable Feedstocks: Closed-loop material systems using bio-based or recycled inputs.

-

Lightweight Design: AI-driven lattice geometries that reduce material use and emissions.

-

Localized Production: 3D printing parts near end-use sites to minimize shipping and logistics waste.

Through partnerships highlighted by 3D Printing Central, companies are proving that sustainable design is both good for the planet and great for business.

“In the new industrial era, efficiency and ecology are no longer opposites — they’re synonyms.”

🧬 7. Stay Informed About Bioprinting and Emerging Frontiers

The next frontier of additive manufacturing isn’t made of metal or plastic — it’s made of life itself.

Bioprinting World showcases breakthroughs in biofabrication, regenerative medicine, and tissue engineering, where 3D printers are being used to replicate living cells and organs.

For those in traditional manufacturing, bioprinting offers lessons in cross-disciplinary innovation:

-

AI and quantum computing accelerate bio-material design.

-

Blockchain ensures ethical data usage and patient privacy.

-

Robotics deliver microscopic precision.

Even if you’re not in healthcare, studying bioprinting can help you anticipate how additive manufacturing will merge with biology, computing, and chemistry over the next decade.

📡 8. Leverage Data and Predictive Intelligence

Data is now the fuel of manufacturing.

Every print generates terabytes of information — from temperature fluctuations to real-time layer quality.

The most successful organizations use predictive analytics to anticipate outcomes and improve performance.

AI-driven dashboards, IoT sensors, and digital twins are enabling continuous optimization.

As 3D Printing Channel reports, manufacturers leveraging AI and data analytics see up to 30% faster production times and 50% fewer material errors — turning data into measurable profit.

🧭 9. Anticipate the Future — Don’t Chase It

The companies leading additive manufacturing today are the ones that think like futurists. They don’t react to trends — they create them.

Stay ahead by:

-

Following global thought leaders through 3D Printing Channel and Association of 3D Printing publications.

-

Tracking emerging investment patterns via 3D Printing Ventures.

-

Watching tokenized ecosystem growth through 3D Printing Coin ($3DP).

-

Studying experimental fields like quantum design and bioprinting via Bioprinting World.

The goal isn’t just to keep up — it’s to see the convergence of technologies before the rest of the market does.

“Additive manufacturing isn’t about keeping pace — it’s about shaping the pace of progress.”

🚀 Conclusion: The Future Belongs to the Connected Innovator

Additive manufacturing is no longer a single industry — it’s a networked movement spanning machines, software, finance, and biology.

To stay ahead, you must:

-

Master the technology stack.

-

Keep learning continuously.

-

Build a global network of collaborators.

-

Embrace automation, sustainability, and tokenization.

Through platforms like 3D Printing Central, 3D Printing Channel, Association of 3D Printing, 3D Printing Ventures, Bioprinting World, and 3D Printing Coin ($3DP), professionals now have everything they need to innovate, connect, and lead in the decade ahead.

“The future of additive manufacturing isn’t built in isolation — it’s built in layers, by those who stay informed, inspired, and interconnected.”

Leave a Reply