Key Challenges and Opportunities in 3D Printing

Navigating the Next Decade of Additive Manufacturing

🌍 Introduction: The Dual Reality of a Revolution

3D printing — once the scrappy underdog of manufacturing — has matured into a $30 billion-plus global industry.

From aerospace to medicine, from rapid prototyping to full-scale production, additive manufacturing (AM) has proven its ability to reshape how we design, build, and distribute products.

But this growth comes with paradoxes: unprecedented potential alongside persistent pain points.

As new technologies like AI, blockchain, and robotics merge with additive processes, the winners will be those who not only innovate, but also solve the industry’s most pressing challenges head-on.

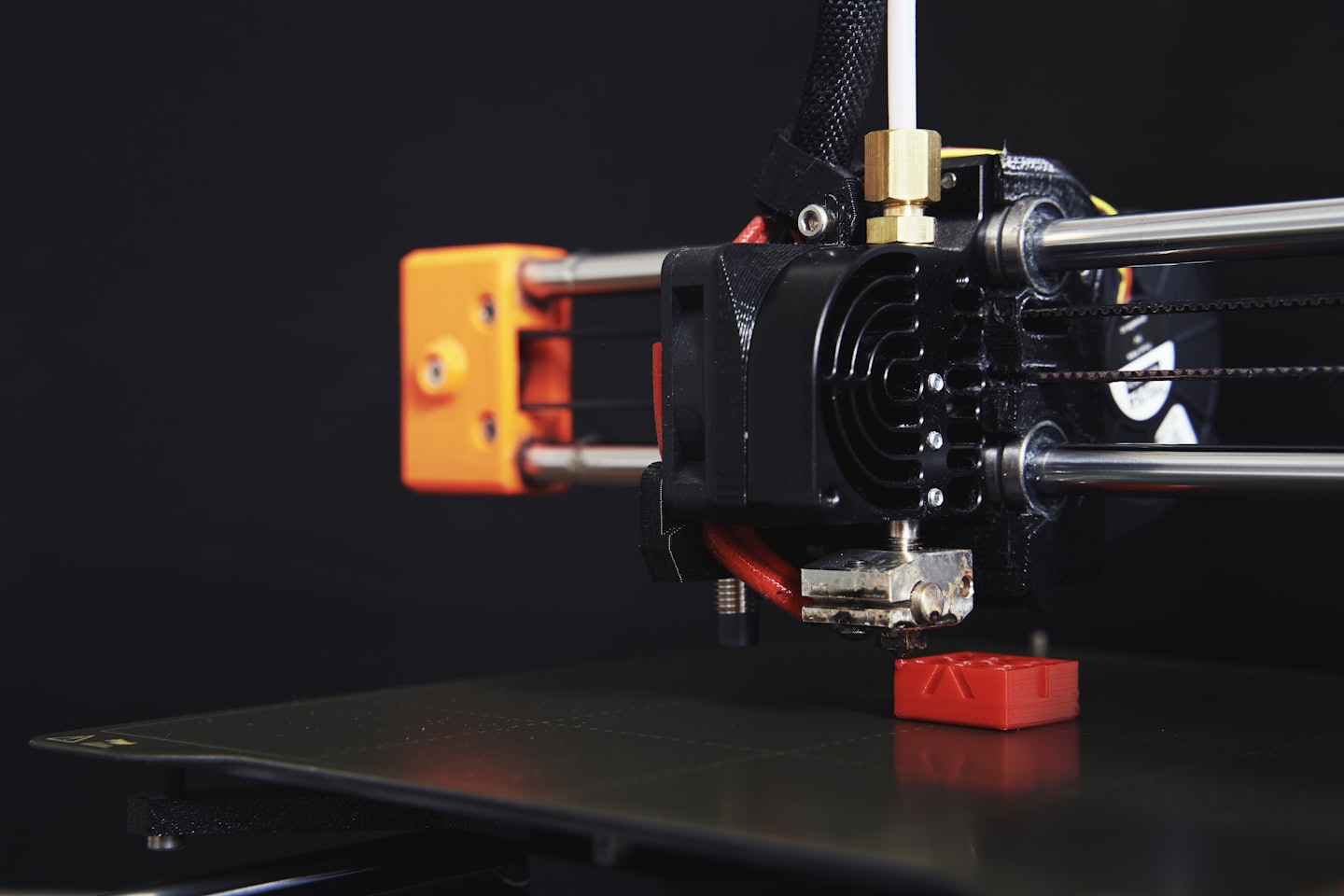

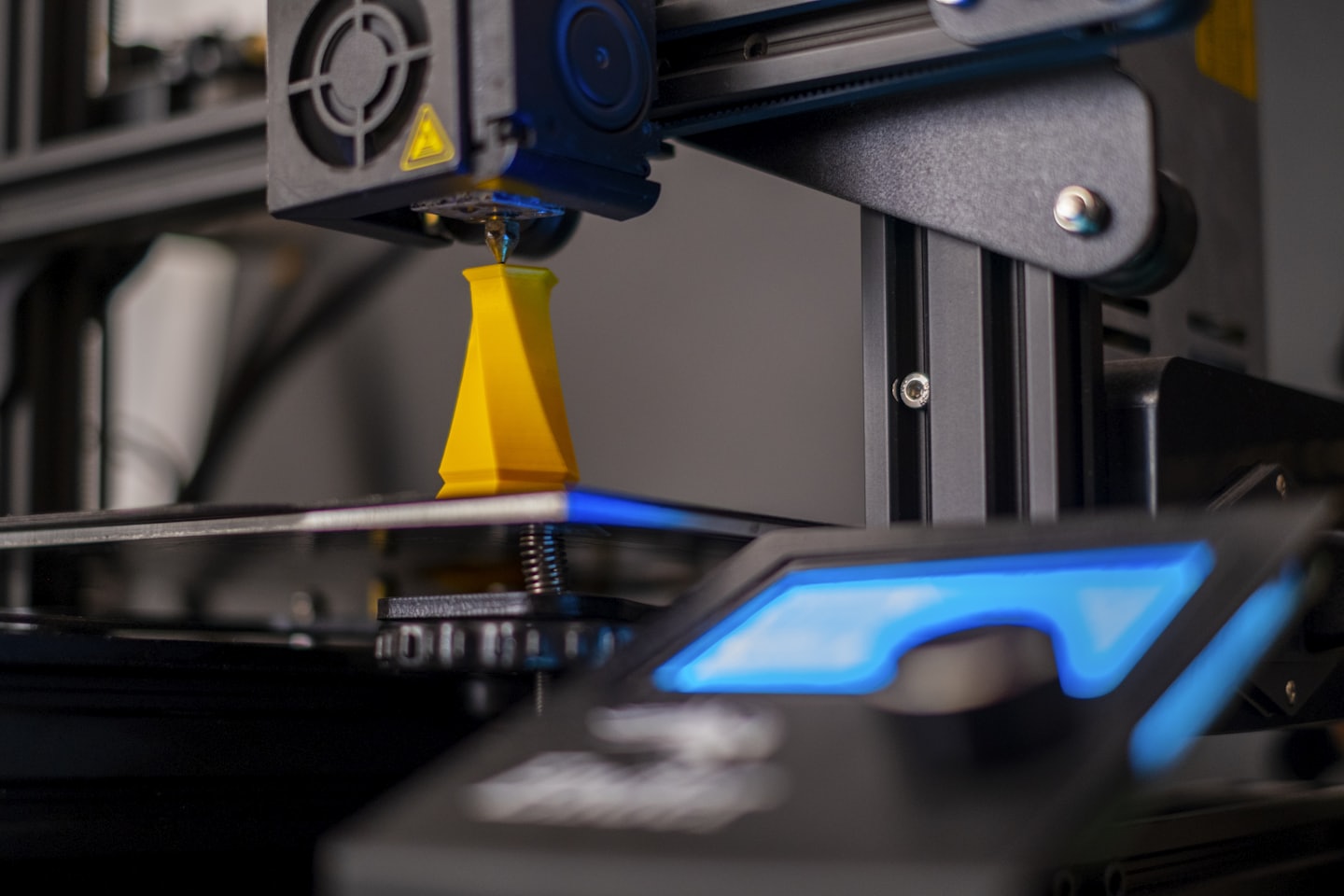

⚙️ Challenge #1: Scaling From Prototyping to Production

3D printing is unrivaled for prototyping — but scaling to high-volume, repeatable production remains a major hurdle.

The bottlenecks:

-

Slow print speeds for large parts.

-

Post-processing time and labor intensity.

-

Lack of standardized quality-control metrics.

The opportunity:

Emerging automated print farms and robotic handling systems (backed by AI process monitoring) are closing the gap.

Companies funded by 3D Printing Ventures are pioneering scalable workflows that integrate 3D printing with traditional manufacturing — hybrid systems where printers handle complexity and CNC lines handle quantity.

“The future factory won’t replace old methods — it will network them.”

💰 Challenge #2: High Material Costs and Limited Diversity

Specialized filaments, resins, and metal powders remain costly, and certification for aerospace- or medical-grade use can take years.

The opportunity:

Innovation in recycled, bio-based, and locally produced feedstocks is booming.

Projects spotlighted on 3D Printing Central and Polymaker’s new composite lines show how advanced polymers and sustainable materials are driving down cost while improving strength-to-weight ratios.

Blockchain-based material tracking, using 3D Printing Coin ($3DP), could further validate provenance and quality — rewarding eco-friendly production with digital incentives.

🧠 Challenge #3: Skills Gap and Workforce Transition

As printers become smarter, the need for multi-disciplinary expertise grows.

The industry lacks professionals fluent in both engineering and digital technologies — people who understand CAD, robotics, AI, and supply-chain data simultaneously.

The opportunity:

Education initiatives like Association of 3D Printing and 3D Printing MBA are filling that gap by teaching additive design, business strategy, and sustainability together.

The next generation of engineers will be system thinkers, not siloed specialists.

🔗 Challenge #4: Data Security and Intellectual Property

In a distributed manufacturing model, CAD files and print instructions travel globally in seconds.

That creates new vulnerabilities: piracy, tampering, or counterfeit parts.

The opportunity:

Blockchain solutions are emerging to tokenize and secure digital blueprints.

Every design can be timestamped, verified, and licensed transparently.

The 3D Printing Channel has documented how blockchain IP protection — paired with smart contracts — is enabling designers to monetize work safely while allowing manufacturers instant, verifiable access.

“Trust is the true currency of digital manufacturing — and blockchain is the mint.”

🦿 Challenge #5: Integration With Robotics and AI

Automation promises efficiency but adds complexity.

Synchronizing robotic arms, conveyor systems, and printers requires seamless communication and adaptive control.

The opportunity:

AI-driven control systems are creating self-optimizing production cells.

In these smart factories — often funded or showcased by 3D Printing Ventures — machines schedule maintenance, adjust parameters, and even reorder materials autonomously.

This marks the dawn of the Machine Economy, where crypto-backed micro-transactions let machines pay each other for services and energy in real time.

🧬 Challenge #6: Bioprinting and Ethical Regulation

Bioprinting World has made it clear: the ability to print living tissues is both a medical miracle and a regulatory minefield.

Governments struggle to define standards for cell-based materials, data privacy, and bio-safety.

The opportunity:

Ethical frameworks and blockchain-secured patient data could accelerate safe clinical adoption.

AI modeling and quantum computing will also help predict cell behavior before printing, dramatically shortening development cycles.

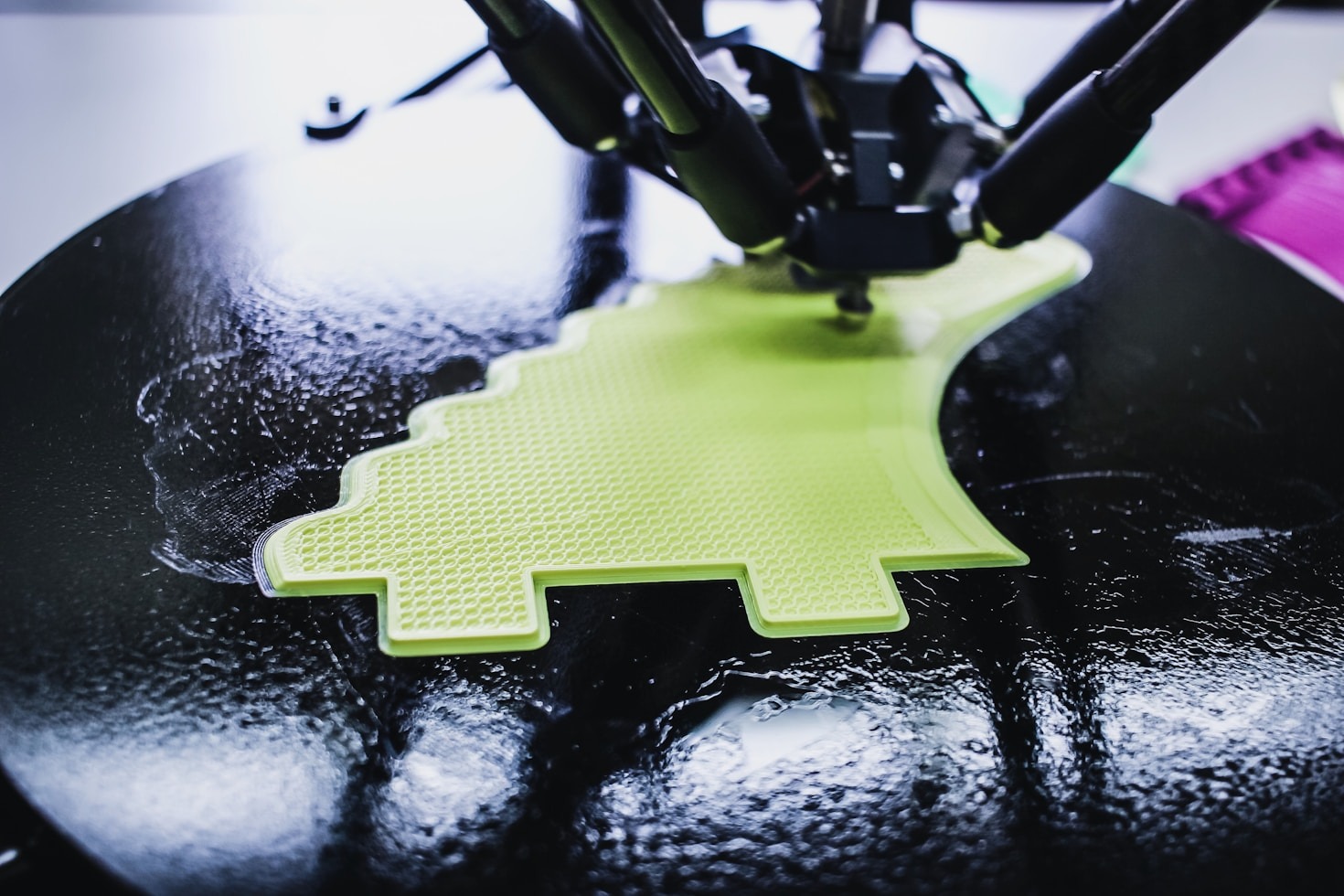

🌱 Challenge #7: Environmental Impact and Energy Use

Although additive manufacturing reduces waste compared to subtractive methods, energy intensity — especially for metal AM — remains high.

The opportunity:

-

Transition to renewable-powered printer farms.

-

Use of recycled metals and polymers.

-

Local, on-demand production reducing shipping emissions.

Sustainability is no longer a branding angle — it’s a performance metric investors and regulators demand.

The 3D Printing Coin ($3DP) initiative envisions a tokenized carbon credit system rewarding green manufacturing nodes.

🧩 Challenge #8: Industry Fragmentation and Standards

Too many printer formats, materials, and software protocols create inefficiencies.

Compatibility issues slow adoption across supply chains.

The opportunity:

Collaborations through the Association of 3D Printing are pushing for unified standards — open filament RFID protocols, interoperable slicer formats, and shared qualification data.

Standardization will unlock global production networks where any certified printer can reproduce any certified part.

🔮 Challenge #9: Investment Volatility and Market Education

Despite growth, investor understanding of AM remains inconsistent. Some see hype; others see hardware risk.

The opportunity:

With the rise of tokenized venture ecosystems like 3D Printing Ventures and $3DP, fractional investment and community funding are democratizing access.

This creates liquidity and transparency while accelerating R&D.

It’s no longer about betting on one company — it’s about owning a piece of the ecosystem.

🏁 Conclusion: Turning Obstacles Into Opportunity

Every great technology cycle begins with turbulence.

Additive manufacturing is no exception — yet its capacity for adaptation, decentralization, and collaboration makes it uniquely equipped to overcome its growing pains.

Through the collective efforts of 3D Printing Central, 3D Printing Channel, Association of 3D Printing, 3D Printing Ventures, Bioprinting World, and the 3D Printing Coin ($3DP) community, these challenges are already being transformed into new frontiers for innovation.

“In 3D printing, every challenge is just another layer in the build — and the more layers we solve, the stronger the structure becomes.”

Leave a Reply