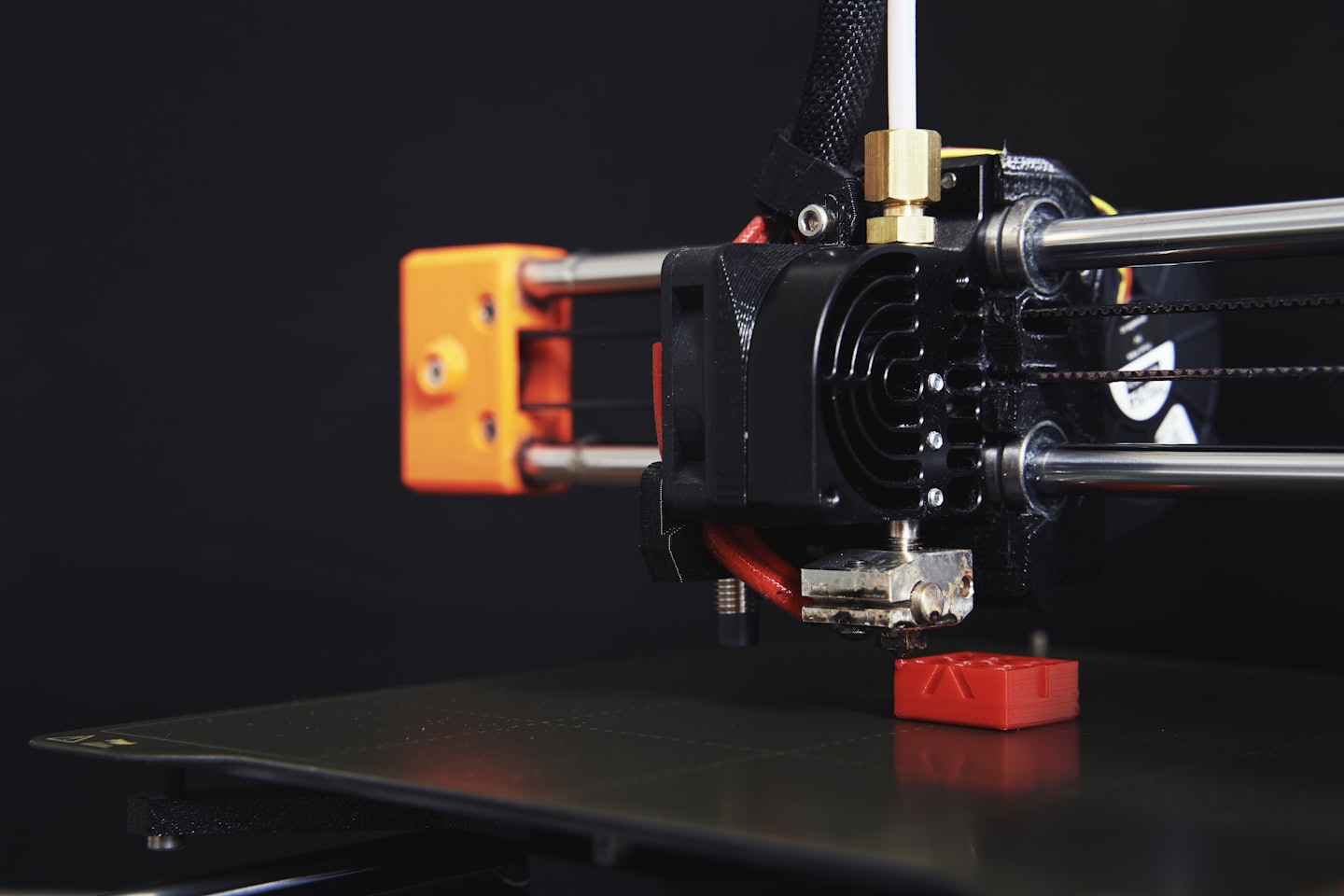

The Next Industrial Convergence: How AI, Blockchain, Robotics, and Quantum Tech Are Redefining 3D Printing

🌍 Introduction: A New Era of Intelligent Manufacturing

We are standing at the crossroads of the most transformative technological shift since the Industrial Revolution. What was once a manufacturing process based on physical molds and centralized factories is now becoming a living, digital ecosystem — intelligent, decentralized, and self-optimizing.

At the center of this transformation is 3D printing, the cornerstone of additive manufacturing. But the revolution doesn’t stop there. The true acceleration comes from its integration with AI, blockchain, robotics, quantum computing, and data systems — forming a new industrial network that is as smart as it is scalable.

This convergence isn’t theoretical. It’s happening right now — across the platforms that define the future of the industry:

-

3D Printing Central — the global hub connecting companies, creators, and investors in the additive world.

-

3D Printing Channel — the media voice of the industry, broadcasting insights, innovation, and expert interviews.

-

Association of 3D Printing — building education, ethics, and standards across the global AM ecosystem.

-

3D Printing Ventures — accelerating startups and technology breakthroughs with strategic investment.

-

3D Printing Coin ($3DP) — tokenizing collaboration, innovation, and digital manufacturing economies.

-

Bioprinting World — exploring how additive technology is transforming medicine, biology, and regenerative science.

Together, these platforms form the 3D Printing Network — a unified digital ecosystem designed to guide the next phase of industrial evolution.

🤖 AI: The Brain Behind Design, Production, and Efficiency

Artificial Intelligence has quickly become the intellectual engine of the 3D printing revolution. It enables machines not just to follow instructions, but to learn, adapt, and optimize in real time.

Key Advancements

-

Generative Design Algorithms: AI tools now design components with biomimetic structures — lighter, stronger, and more resource-efficient than anything humans could draw manually.

-

Automated Quality Control: AI-driven sensors and cameras inspect prints during production, identifying micro-defects invisible to the human eye.

-

Predictive Manufacturing: Machine learning anticipates machine failures and material issues before they happen, reducing downtime.

At 3D Printing Channel, experts are already showcasing how AI-driven systems are transforming production floors into self-correcting ecosystems, where machines communicate and collaborate — not unlike living organisms.

“Artificial intelligence allows additive manufacturing to think, learn, and evolve — one layer at a time.”

🔗 Blockchain: The Trust Framework of Digital Manufacturing

As manufacturing becomes more distributed, blockchain becomes the security and transparency backbone that ties the ecosystem together.

Every design, machine transaction, and material movement can now be verified, timestamped, and tokenized — ensuring integrity and accountability across the global supply chain.

Blockchain in Additive Manufacturing

-

Design Protection: Original 3D models can be stored on decentralized ledgers, safeguarding against IP theft.

-

Smart Contracts: Automate supplier payments and project milestones when digital proofs are validated.

-

Tokenized Production: Machines and projects can issue blockchain-based tokens representing production rights or investment shares.

-

Traceability: From powder source to finished product, every step is recorded immutably.

The Association of 3D Printing is championing these principles through its work in developing digital standards and blockchain-backed certification systems — ensuring that decentralized manufacturing remains both ethical and verifiable.

Meanwhile, 3D Printing Coin ($3DP) is bringing financial life to this model — enabling global collaboration through tokenized rewards and open innovation funding.

“Blockchain doesn’t just track production — it transforms it into a transparent, trustless ecosystem.”

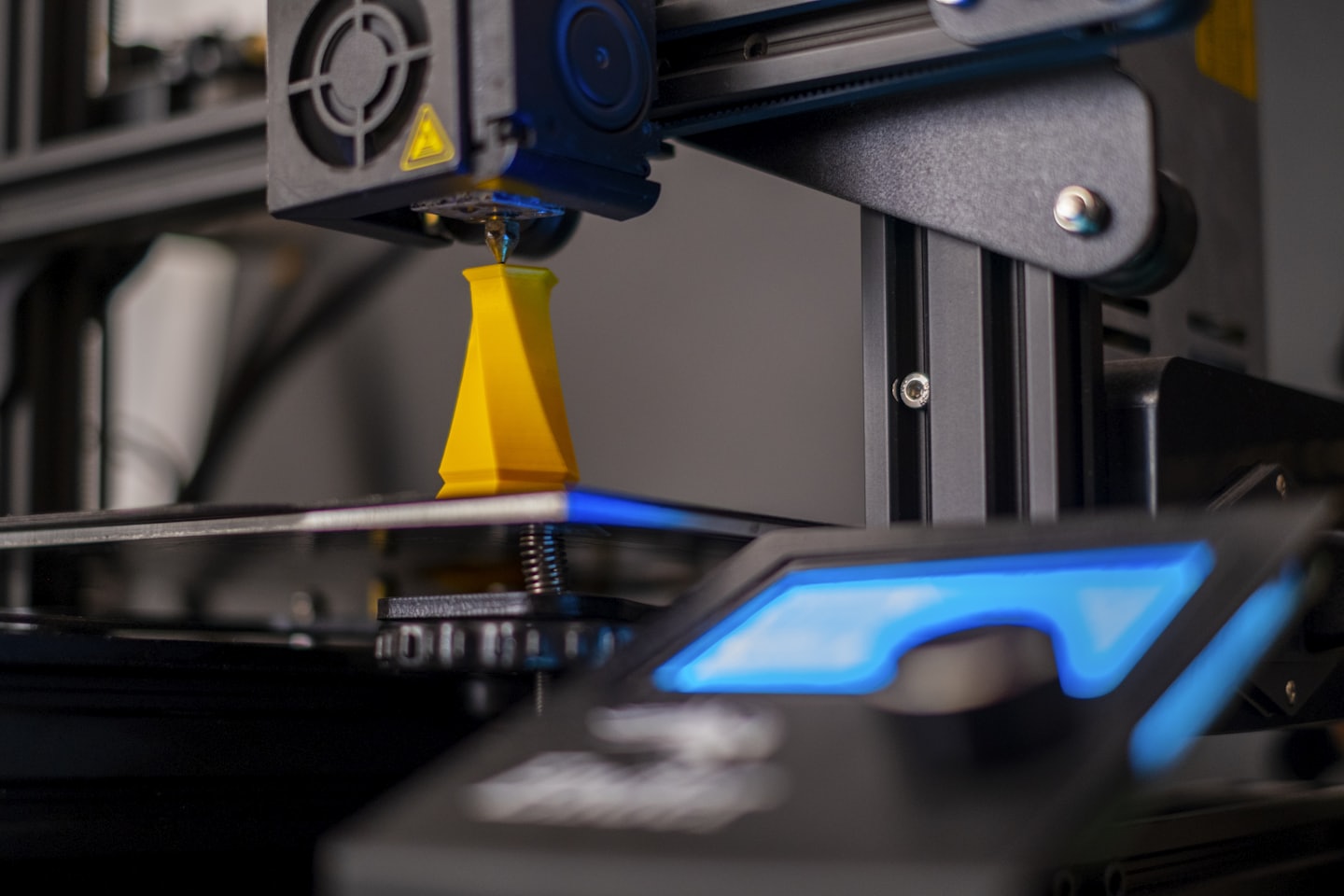

🦿 Robotics: The Hands and Motion of Intelligent Fabrication

If AI is the brain and blockchain is the nervous system, robotics is the muscle of this new industrial body.

Robotic systems integrated with additive manufacturing are enabling autonomous, large-scale, continuous production.

Innovations on the Factory Floor

-

Robotic 3D Printers: Articulated robotic arms are now capable of printing houses, aircraft components, and even bridges.

-

Collaborative Robots (Cobots): Working alongside humans, cobots handle repetitive tasks like part assembly, material delivery, and post-processing.

-

Swarm Manufacturing: Fleets of mobile 3D printers coordinate together — an innovation inspired by nature’s hive intelligence.

At 3D Printing Ventures, investment focus is shifting toward startups developing robotic fabrication systems that merge precision engineering with adaptive intelligence. These machines are not only reshaping factories — they’re redefining the concept of a factory itself.

“The future of production isn’t one big factory — it’s a million smart robots working together in perfect harmony.”

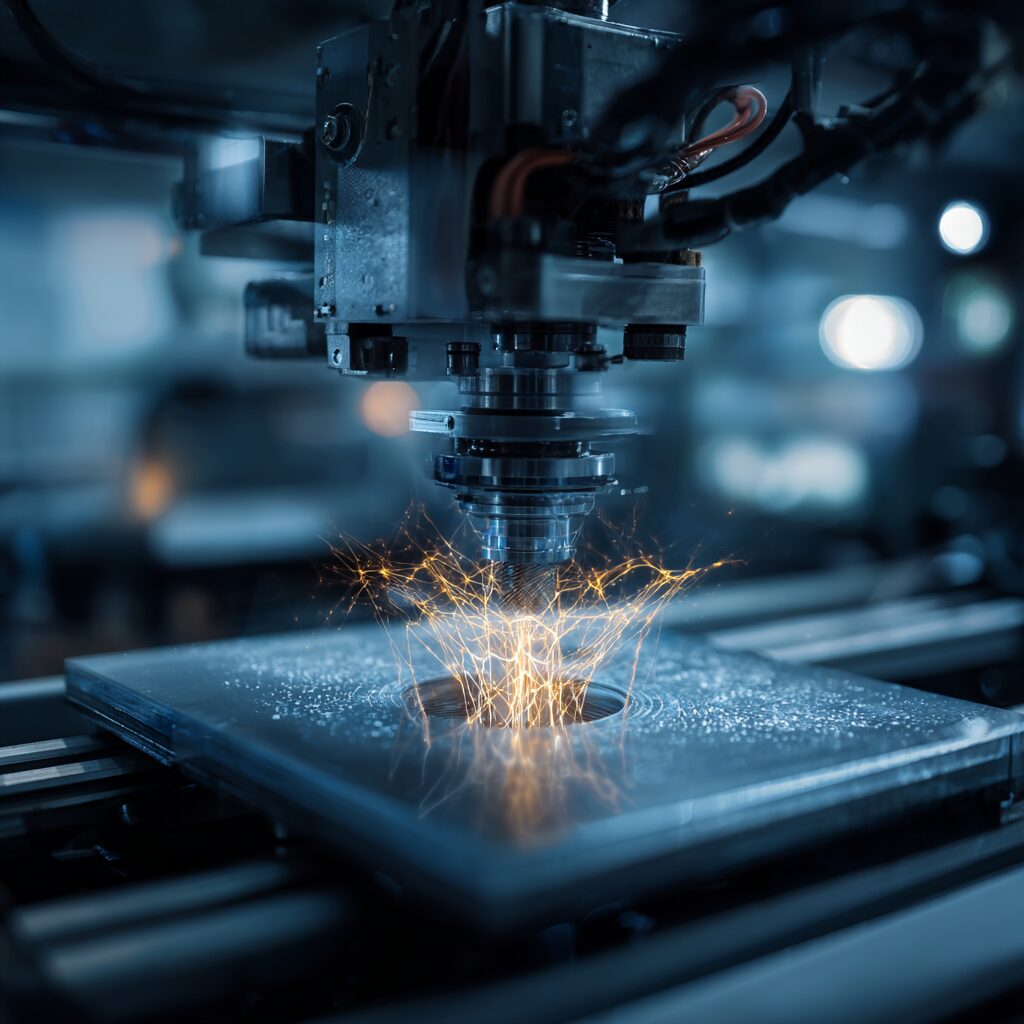

⚛️ Quantum Computing: The Catalyst of Material Discovery

Quantum computing promises to rewrite the rules of materials science — unlocking new alloys, polymers, and composites specifically engineered for 3D printing.

Unlike classical computers, quantum systems process information in superposition, allowing them to simulate complex atomic interactions that determine how materials behave.

Quantum Breakthroughs Ahead

-

Material Simulation: Designing molecular-level structures for stronger, lighter, and more sustainable materials.

-

Error Correction Models: Predicting and preventing warping, cracking, or bonding defects in real time.

-

Optimization Algorithms: Perfecting printer parameters and energy use based on live feedback.

As part of the 3D Printing Network, Bioprinting World is particularly interested in how quantum simulation may accelerate breakthroughs in cellular bioinks and tissue scaffolds, pushing bioprinting closer to the dream of printing living organs.

🧠 Data, Decentralization, and the Rise of Smart Manufacturing

Behind every successful additive process is data — design data, sensor data, environmental data, and blockchain-verified production data. The next evolution of manufacturing will depend on how well we collect, connect, and analyze these streams.

Data centers and cloud platforms now act as digital foundries — places where design intelligence is refined, stored, and shared securely across continents.

With blockchain as its foundation and AI as its interpreter, decentralized data ecosystems are giving birth to the autonomous factories of tomorrow — where design, production, and financing merge seamlessly into one intelligent loop.

This is where 3D Printing Central plays a vital role — connecting these systems, curating verified resources, and serving as the digital hub where information becomes innovation.

🧬 Bioprinting: Where Technology Meets Life

The convergence of biotech and 3D printing represents the most human dimension of this industrial renaissance.

At Bioprinting World, scientists, engineers, and physicians are exploring how 3D-printed living materials — tissues, organs, and bio-scaffolds — can revolutionize healthcare.

AI assists in optimizing tissue structures, while blockchain secures patient-specific design data, and quantum simulation predicts biocompatibility — creating a fusion of biology and computation that could redefine medicine itself.

“Bioprinting isn’t just manufacturing — it’s creation at the molecular level.”

🌐 The 3D Printing Network: Building the Infrastructure of Innovation

The additive industry’s greatest strength is not in any single machine, but in the network of intelligence and collaboration connecting them.

The 3D Printing Network — composed of

-

3D Printing Central (business + directory hub),

-

3D Printing Channel (media + communication),

-

Association of 3D Printing (standards + education),

-

3D Printing Ventures (investment + acceleration),

-

3D Printing Coin ($3DP) (tokenization + decentralization), and

-

Bioprinting World (research + biotech frontier),

— represents the next evolution of industrial connectivity.

Together, they embody a living ecosystem of innovation where technology, economics, and creativity evolve hand in hand.

🚀 Conclusion: Printing the Future, One Layer at a Time

The fusion of AI, blockchain, robotics, quantum computing, and biotechnology isn’t just changing how we print — it’s changing how we think about creation itself.

Through collaboration across platforms like 3D Printing Central and its partner networks, we’re witnessing the birth of a machine-intelligent, tokenized, and globally connected industrial civilization — one that values transparency, efficiency, and imagination above all else.

“In the new industrial age, factories don’t just build products — they build progress.”

Leave a Reply